Stay tuned for exciting announcements about HHP Summit 2018 project tours!

At HHP Summit 2017, attendees had the unique opportunity to see examples of North America’s exciting natural gas HHP market momentum firsthand. Attendees visited operational natural gas marine, rail, and on-road trucking projects, as well as several brand new natural gas infrastructure and bunkering projects that provide customers with a stable supply of low-cost, reliable, low-emission, domestically produced fuel. Off-site tours included:

JAX LNG Plant and TOTE Terminal Tour

SPONSORED BY

PROJECT PARTNERS & CO-SPONSORS

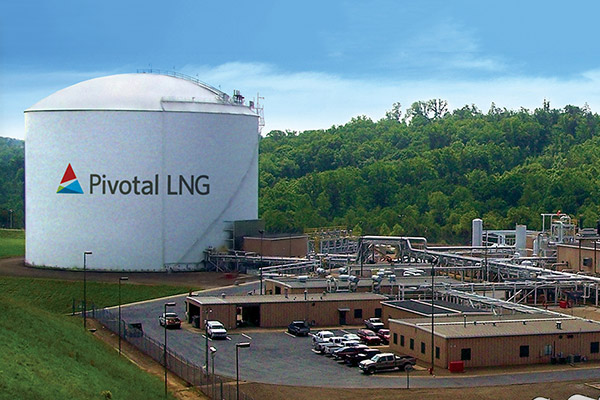

This “tour of many firsts” showcased the pioneering work of TOTE and Pivotal LNG, two of the earliest market movers in the North American LNG marine market. Attendees got a comprehensive look at the entire LNG fuel supply chain, starting with the JAX LNG production facility, a newly constructed small-scale coastal LNG facility which is the first in North America and a joint venture between Pivotal LNG and NorthStar Midstream. This facility will load North America’s first LNG bunkering barge, which will then maneuver to TOTE’s berth to provide LNG bunkering services to its two first-in-the-world LNG-powered container ships. From the JAX LNG plant, the tour continued to TOTE’s Blount Island Terminal where attendees got an up-close look at the innovative on-dock ISO-tank LNG bunkering facility that has served TOTE’s vessels for more than a year. This on-dock tour provided an overview of the TOTE LNG container ship that was at the dock, as well as its LNG bunkering operation.

UPS LNG and Jacksonville Transit Authority CNG Station Tour

SPONSORED BY

PROJECT PARTNERS & CO-SPONSORS

HHP Summit hosted a tour of two high-volume natural gas fueling stations. The tour began with an inside look at UPS’s LNG fueling facility, one of the largest in the world, and supporting a 125+ truck operation. The tour continued at Jacksonville Transit Authority’s public access CNG station which provides fuel for the Authority’s own fleet of natural gas buses; a fleet projected to increase to 100 vehicles over the next three years.

Eagle LNG Maxville Plant and Crowley LNG Bunker Terminal Tour

SPONSORED BY

PROJECT PARTNERS & CO-SPONSORS

Crowley’s innovative on-dock LNG storage and bunkering operation was front and center on this tour. The two 1,000 cubic meter LNG storage tanks from Chart are each 170-feet long and truly a sight to see up close. These tanks hold more than 500,000 liters of LNG, which is stored on site and delivered to Crowley’s LNG-powered ConRo ships via a cutting-edge pumping and bunkering system. Fuel for this storage and bunkering facility will be provided by the nearby Maxville LNG production plant, a brand new state-of-the-art facility which includes a high-efficiency nitrogen-cycle Cosmodyne liquefier and a 1,000,000 gallon cryogenic tank provided by Matrix Service being constructed by Eagle LNG. The LNG plant and on-dock bunkering installation gave tour attendees a comprehensive look at the entire supply chain for modern LNG-powered vessel operations and other high horsepower customer segments.

Florida East Coast Railway LNG Operations Tour

HOSTED BY

In November 2014, Florida East Coast Railway (FECR) initiated the deployment of 24 new LNG-powered locomotives. These 4400 HP Tier 3 emissions compliant locomotives now make up FECR’s entire mainline thru-haul fleet operating between Jacksonville and Miami. With the conversion project just recently completed, HHP attendees were the first-ever tour of LNG operations at FECR’s Bowden Yard in Jacksonville. This was a unique opportunity to see firsthand this pioneering LNG locomotive project. On display was an LNG-powered locomotive and tender car, an ISO container used to transport the gas, and an LNG tanker delivery trailer hauled by an LNG-powered truck.